Link to Article:

A Look Inside- APD's MPTCC TU Class Killer Acura TSX

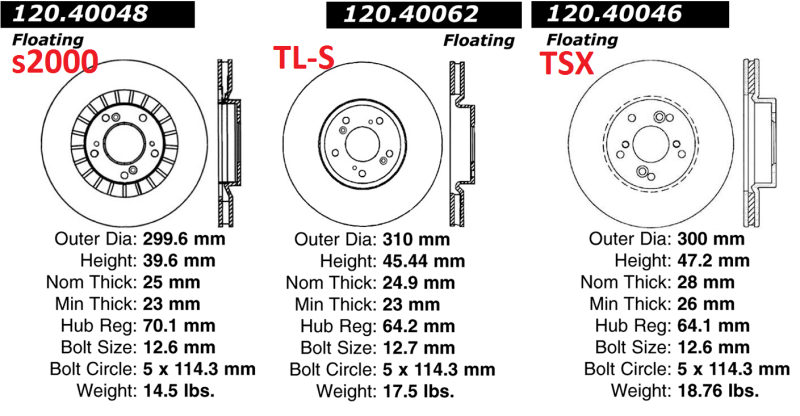

The front brakes use stock Acura/Honda parts to develop a big brake option at a fraction of the cost of traditional race big brake kits. The factory ABS is left in place which allows extremely late, deep and confident braking. The stock knuckles were drilled out to accept larger OD Acura TL mounting bolts which in turn allowed the mounting of Acura/Brembo TL Type S, 4 Piston Calipers clamping Honda S2000 rotors.

![Image]()

An inexpensive big brake kit was made with this Acura caliper which just happens to be made by Brembo teamed up with an S2000 rotor.

![Image]()

The spindle was bored out to accept the larger bolts that the Brembo calipers require.

Custom machined 6mm hub and wheel centric spacers are used that can adapt 3 different hub bore sizes and space things out 6mm for caliper to wheel clearance. ARP Extended Race Studs, Skunk 2 Aluminum Race Lugs, Hawk DTC 60 Pads, Goodrich Stainless lines and Brembo LCF600 Fluid are used. The rear brakes use stock rotors and calipers, Hawk DTC 60 pads and Goodrich Stainless lines.

![Image]()

Brembo calipers, S2000 rotors, long studs, hubcentric spacers and braided steel brake lines look sharp!

A Look Inside- APD's MPTCC TU Class Killer Acura TSX

The front brakes use stock Acura/Honda parts to develop a big brake option at a fraction of the cost of traditional race big brake kits. The factory ABS is left in place which allows extremely late, deep and confident braking. The stock knuckles were drilled out to accept larger OD Acura TL mounting bolts which in turn allowed the mounting of Acura/Brembo TL Type S, 4 Piston Calipers clamping Honda S2000 rotors.

An inexpensive big brake kit was made with this Acura caliper which just happens to be made by Brembo teamed up with an S2000 rotor.

The spindle was bored out to accept the larger bolts that the Brembo calipers require.

Custom machined 6mm hub and wheel centric spacers are used that can adapt 3 different hub bore sizes and space things out 6mm for caliper to wheel clearance. ARP Extended Race Studs, Skunk 2 Aluminum Race Lugs, Hawk DTC 60 Pads, Goodrich Stainless lines and Brembo LCF600 Fluid are used. The rear brakes use stock rotors and calipers, Hawk DTC 60 pads and Goodrich Stainless lines.

Brembo calipers, S2000 rotors, long studs, hubcentric spacers and braided steel brake lines look sharp!